Many times clients will walk into a showroom and say to me “show me a good cabinet”, and I’m always disappointed in this line of thinking.

I will then try to explain to the clients that “good” is a relative term and what’s good for one client may not be good for another. You need to be able to choose what’s important in your design and emphasize those as priorities in selecting a cabinet.

That being said, in the world of cabinets, there are a number of basic items that have become somewhat standard: soft closing doors & drawers, plywood construction, and dovetailed drawer boxes are the MOST BASIC of features that people request and expect in my area.

But there are a number of items that you can also look for that indicate a certain level of quality in a cabinet manufacturer.

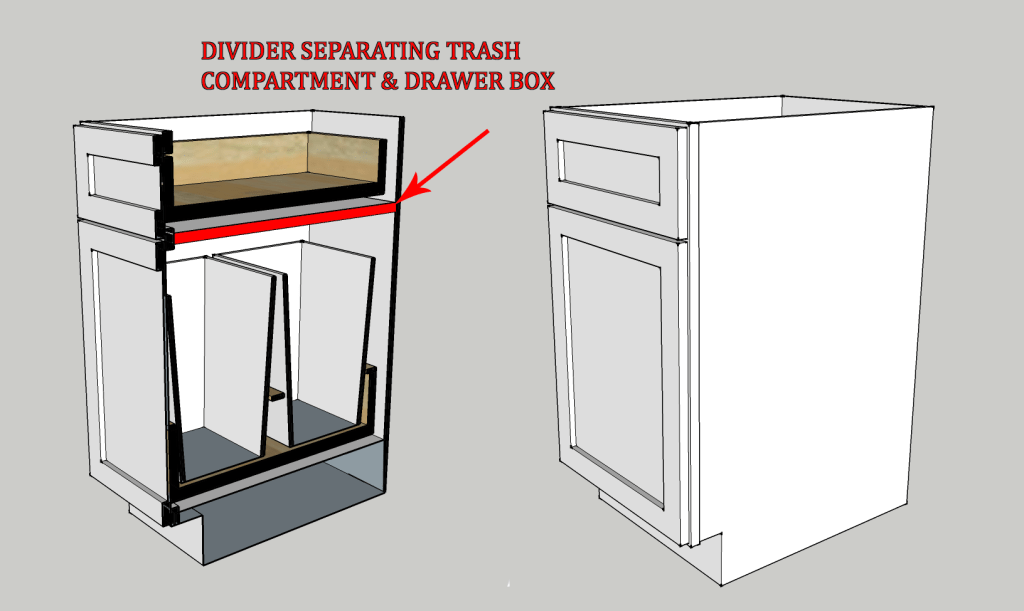

1.) Trash cabinets that divide the trash compartment from the drawer box

Companies that add an extra piece of plywood between the trash compartment of a pullout trash cabinet and the drawer box show a company that thinks about its customers and realizes that there’s a sanity issue here. Pullout trash cabinets that neglect to have this divider pose a potential sanity risk to anything stored in the drawer above the trash. Frequently I see people keeping cutlery in this drawer and if you don’t have a divider, you’re keeping your eating utensils very close to a source of contaminating bacteria.

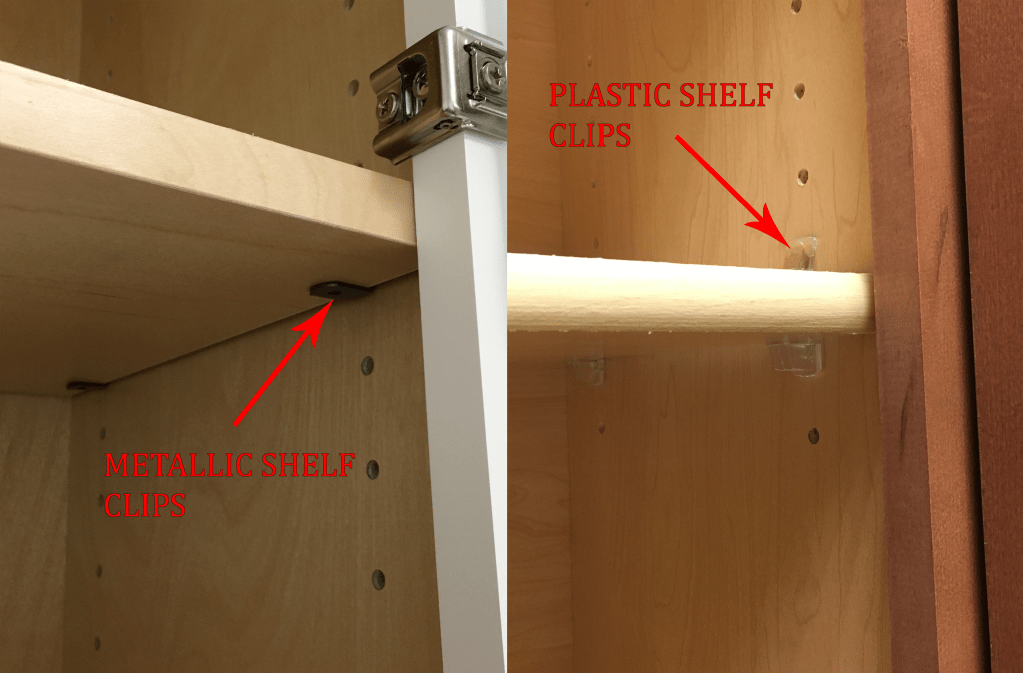

2.) Metal Shelf Clips VS Plastic Shelf Clips

Metallic shelf clips will last longer than plastic ones. Plastic has a tendency to become brittle with time. Quickly taking a look at these while you’re shopping for cabinets and familiarizing yourself with the options available may help to sway you from one cabinet line to the next. Below you’ll see an example of metallic shelf clips as well as a lower quality plastic clip. Make sure to speak with your designer though- some cabinets lines ship you a shelf with a plastic “shipping clip” to hold the shelf in place during delivery, that needs to be changed out once they’re installed. Make sure to check that your installer does this as I’ve seen more than once where the installer doesn’t realize and leaves it as is.

3.) Name brand hinges & drawer glides

Not all hinges and glides are created equally. Just because your designer tells you they’re “soft close” doesn’t mean much at all except just that, they’ll close softly. But how long will they last? Who will provide a replacement if there’s a defect? Choosing a cabinet line that uses a name brand hinge and glide is the best possible option for longevity in the kitchen & bath. Remember, these are the moving parts of a cabinet, the pieces that will get a fair amount of use over the lifetime of the cabinet, and you don’t want to use something that doesn’t have a quality company behind it.

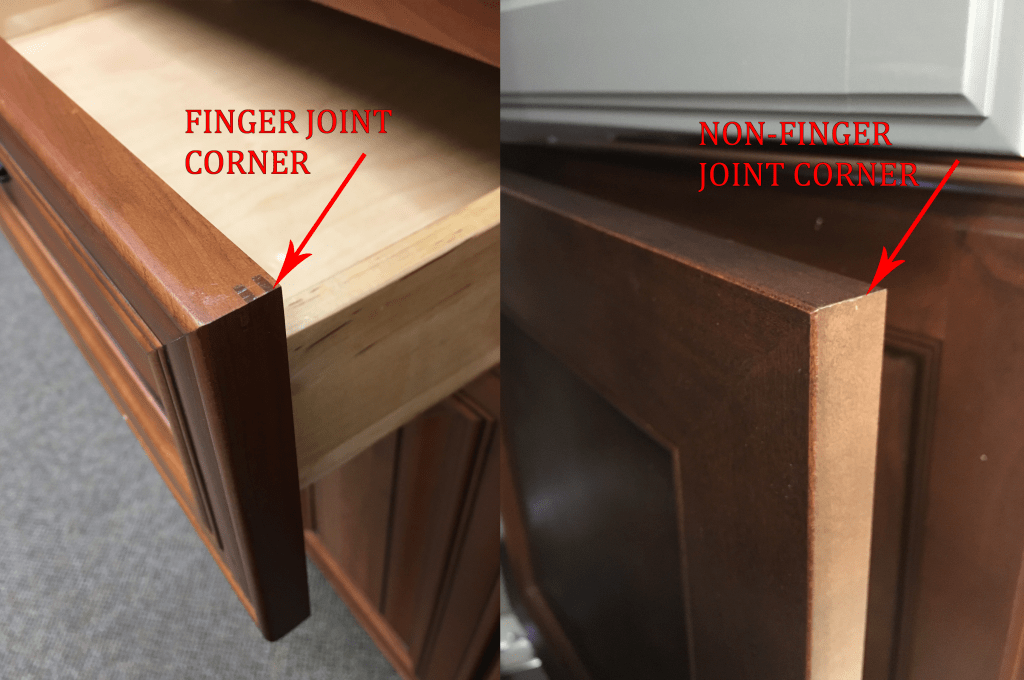

4.) Finger jointed mitered door corners

This only applies to a mitered door- that is a door that has a corner with a 45 degree angle, similar to a picture frame. Mitered doors are notorious for having issues with the miter opening, usually due to changes in temperature and humidity. A quality company is going to try and prevent this miter from opening, using a finger joint that allows the miter to be stronger. This will be hard to see on a painted cabinet, but will be evident on a stained cabinet. If you’re unsure, make sure to ask your designer, and always get it in writing.

5.) Wood veneer sides VS laminate sides

This is often overlooked and can sometimes be deceiving unless verifying with a specification sheet. The exterior sides of a cabinet are typically of two different materials- a wood veneer on plywood or furniture board that is then stained or painted to match the rest of the cabinet; or a laminate veneer on plywood or furniture board that is a match to the stain or paint on the cabinet. Notice the word, “match”. When a cabinet is exposed to sunlight over a number of years, it will begin to age. If you don’t use the same material on the doors of the cabinet that you use on the side of a cabinet, you could see some irregular wear over time. I usually recommend using a cabinet that utilizes uniform materials on all sides.

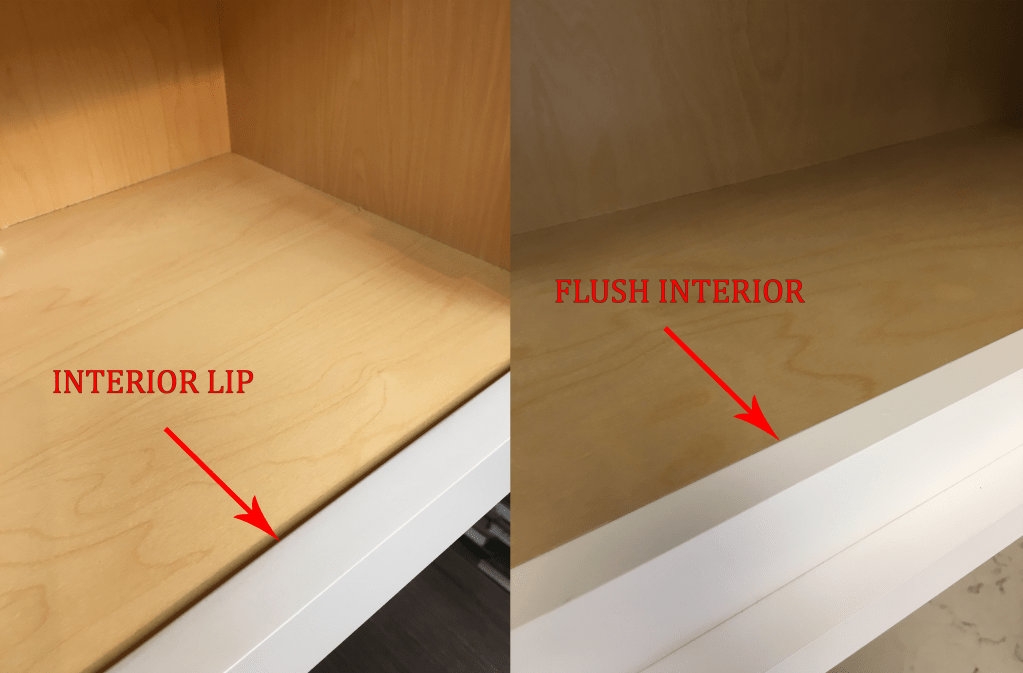

6.) Flush interior bottoms

This applies only to a framed cabinet. Framed cabinets consist of a frame that sits on the cabinet box. Doors and drawers can sit on top of or within this frame. Due to this frame, the sides, top, and bottom of the cabinet are dadoed, or inserted into a groove in this frame to securely hold it in place. Because of this dado, this usually creates a lip on the inside edges and top and bottom of the cabinet. Certain companies will offset this dado to create a flush bottom, so that when removing a glass or dish you don’t nick the lip creating damage or unsightly dents.

7.) Concealed door pin holes

Cabinet doors are held together through a number of ways. The best connection is going to be through the use of a glue and rigid fasteners like a finish nail. Quality companies are going to fabricate a door and use a finish nail to hold the door together, but they’ll also fill the nail hole and paint over it so that you don’t see it when opening the door. A company that doesn’t do this is essentially skipping a step that will result in a lower quality product.

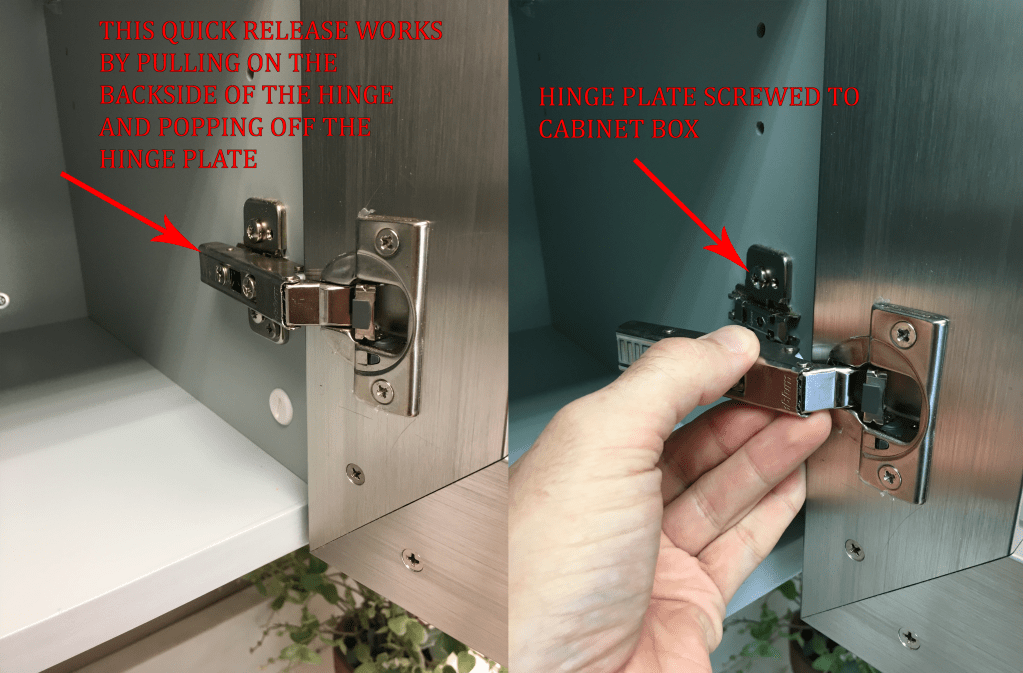

8.) Quick Release Hinges

A newer item that has become more popular is a quick release hinge. These hinges are composed of two separate parts that snap together and remove easily. Cabinet companies that use these are going to be paying a little more for the item and as such will cost a little more. This makes the installers life easier as they don’t have to unscrew the door to remove it while hanging the cabinets- they simply pop off and snap on again. This also makes it easier for the homeowner should they need to remove a cabinet door- they don’t need to unscrew anything, just pop off and pop on again.

9.) Packaging- less is more

This sounds somewhat contrary, but in my experience, the less packaging a cabinet has, typically the higher end it is. Now I’m not talking about a cabinet in a box with shoddy packaging- I’m saying if your cabinets come in a truck, “blanket wrapped”, with shipping blankets- that is typically of a higher quality than a cabinet that comes completely packed in styrofoam. This is because the company that shipped it knows it’s going to get beat up and NEEDS to completely package it in styrofoam or they’re going to be replacing cabinets left and right.

10.) Hinge screw covers

It’s the little things, right? Some cabinet companies are going to produce extra little covers that will conceal where the hinge is screwed into the cabinet box. These little extra details are clear signs that a company really cares about the end result of the cabinet installation and wants to make sure you get a certain aesthetic.