I’ve tried my best to learn from what I see people doing, but there always seem to be certain trends that even seasoned professionals can make. These are just a handful of what I witness regularly.

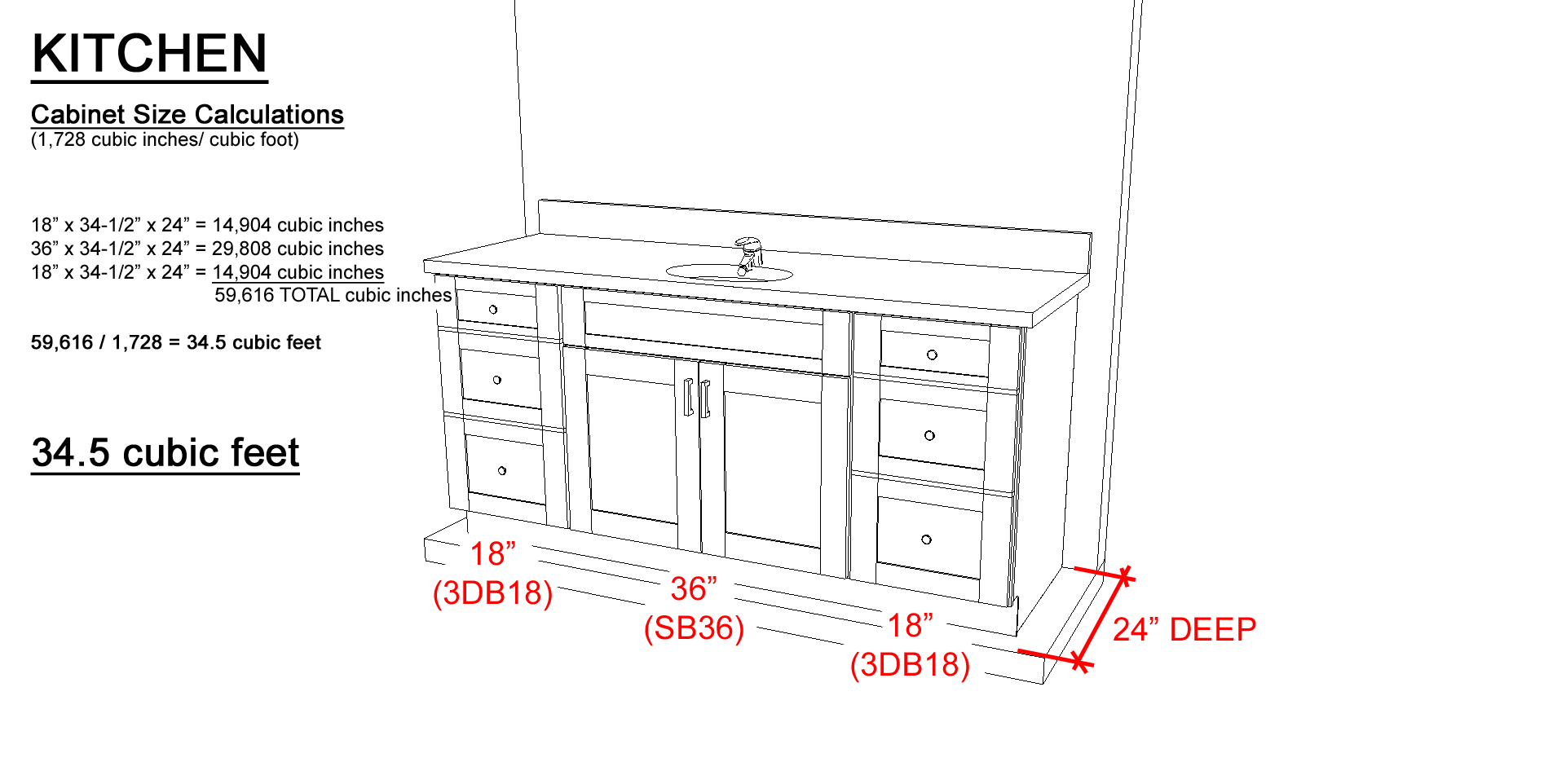

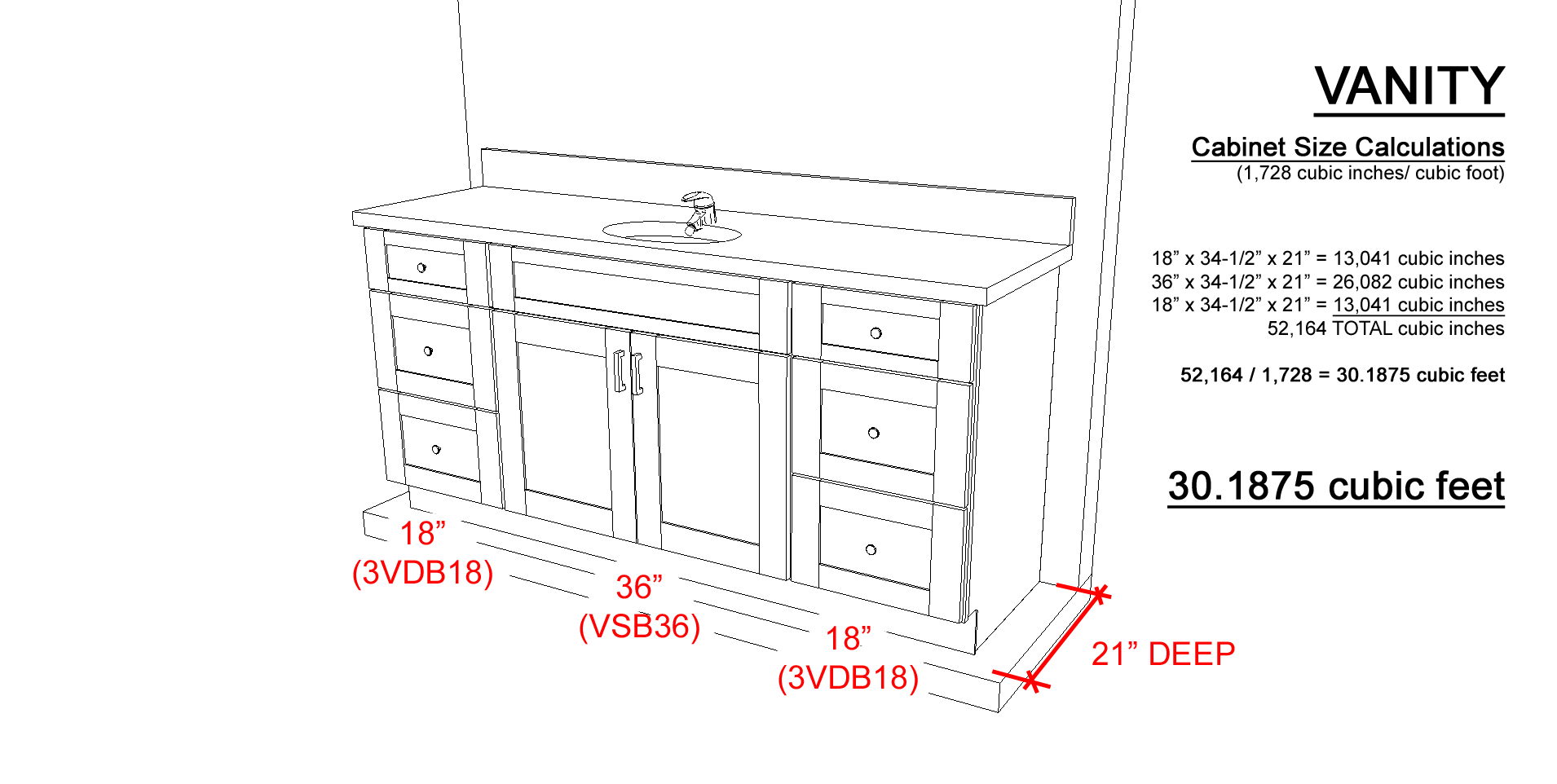

“Trying to pack 10 lbs in a 5 lb bag“

The most common and basic mistake I see people making is trying to pack too many items into a small space. They become hypnotized by photoshopped Instagram images and staged television spaces. They see the kitchen with the double oven, the pantry, the island with the wine refrigerator and seating, the wood hearth style hood with pullouts on either side, the 48” wide cooktop with drawers below and the 42” apron sink. Then they bring my a floor plan that is 10’x10’- a fraction of the 25’ x 35’ kitchen they’re showing me in photos. They think they’re clever when they give me specifications for the smallest possible model of the pro range. And they don’t understand when I start to explain that the choices they’ve made are why the kitchen feels and looks so cramped. Often this becomes an exercise of a client telling me what they want, me explaining why it won’t work and a solution to scaling the concept back, and the client insisting on wanting it their way. Then I’ll take the time to price the option out and show them a visual. It’s usually only when I show them the tight spaces required to accomplish the design or how little countertop space they’ll have before they realize maybe it’s too much for the space. Sometimes they don’t realize this until it’s far too late.

Remodeling things out of order/ trying to get things done out of order

Remember the order of operations from grade school? Well in remodeling there is often a loose set of operations that you should follow. I say loose because there are some items that are more loosey completed. But then there are those that really must come before another. Often clients don’t understand how critical this can be if something is missed or overlooked, or worse, pushed ahead without having made a decision. I have personally had the experience where you’re standing in a room full of demolition debris where they’ve not completed removing items and the electrician is in the corner trying to install the new island lights- BEFORE ANYTHING ELSE WAS INSTALLED. Finished lighting trim should have been one of the very LAST things to be done in this kitchen project and here this client was bringing in an electrician before demolition was complete. The chances that this lighting would get damaged before the project finished were astronomical. We did not end up taking the job.

Overlooking necessary maintenance & focusing on cosmetics

This can be maddening. I’ve walked into too many old homes, with kitchens that haven’t been touched in 30 years, and the client wants to install a countertop. This situation occurs when the client wants to change out their laminate countertops for granite, but I can still see the paneled walls and shag carpets in the living room. Now, I get it- everyone has a budget and (most) people can’t be replacing their kitchen every year, but all too often these same clients mention how they plan to replace their cabinets in a few years, to which I always have to stop, turn to them and remind them of the previous mistake. They’re doing things backwards, and because they haven’t done much in the last 40 years of owning the home, now they’re way behind and the projects they do are going to be costly, instead of doing some basic projects every few years over the last 4 centuries.

Lack of a contingency budget

Unfortunately remodeling homes can be like feeling your way along in the dark, sometimes literally. At best, you’ve got a builder who has a VERY dim flashlight to help you navigate the process. But all too often we have NO IDEA what we’re getting into when we begin a remodeling project. We don’t know what we’ll find behind the walls, what kind of “handyman special” we’re going to find, or who was there before us. There’s always an unknown to this industry and honestly that can be daunting, even for us on the other side of things, trying to console a concerned client. But it’s also very important for clients to be entering into things with a realistic mindset. Shit happens. People fuck up. Things don’t get ordered on time. Delays occur. Acts of god happen. You need to be prepared for contingencies and most projects that come across my desk have a $0 contingency fund. This is a problem- don’t do it. I’ve heard all sorts of figures, depending on the size of project. Usually in residential construction I’ve heard 10% but it should be on a case by case basis.

Not knowing how to choose sub-contractors

I’ve seen it so many times- the frightened and excited look in their eyes. They’re excited about their project, but reality is setting in. They’re starting to get bids back and realizing how much this is actually going to cost them and now that they’ve got some quotes for installation and they’re thinking about going with the guy that’s half the price of the other guy. Usually this other guy is half the price for a reason and it’s so important to investigate and understand WHY this other guy is half the price. You need to remember that your job as a project manager (remember you the homeowner taking on their own project is now the project manager) is to determine which sub contractors will fit well on your job. Tips for choosing subcontrators are to really interview them, have them come over and go over your project. Do they fit well with your personality or do they rub you the wrong way? Ask them questions about their history, past projects, and their workers? How do they work- do they have all subcontractors? Ask them for refernces and actually follow up on them, maybe going so far as to asking to see some of their work in person? Ask them for copies of their insurances and licenses. Ask them how they’ll run the job- will they be onsite themselves? Will they deal with neighbors who have issues with consturction noise, parking, deliveries, etc? And remember, anyone who pushes you to not further investigate them or their work does not deserve your business.

Custom Features may not appeal to future buyers

Usually I encourage people to not worry about future buyers, but occasionally I’ll get a client who has very specific tastes. In these cases I make sure to advise the client to try to appeal to a wide audience of buyers. For instance if someone came in and wanted a bright yellow, super modern kitchen (this has happened), I’d advise them that this is a giant risk and that they’d better be sure that they love this color and don’t mind taking a hit on the potential sale if a buyer feels they’ll need to redo the space. Other features I’ve seen are things like custom hidden gun locations, increased height base cabinets for taller people, extra deep cabinets, and other unique features/modifications that only appeal to a fraction of the market.

Unlicensed contractors can cost more in the long run

Too many times I’ve seen clients get a sub par project because they went with the truck and ladder guy down the street instead of the guy who’s part of the home builders association and was a bit higher. Too often people make decisions based simply on numbers and the bottom line. They don’t look into credentials for builders, what associations they might be a part of, and how they might invest into their own business. Builders, remodelers, installers, designers, and anyone in this industry who go above and beyond will tend to rise to the top and begin to charge higher prices, this is a reality that should not be ignored. They’re charging higher prices for a reason- oftentimes because they are BETTER than the next guy. Part of the problem with these great guys though is just that- because they’re better they’ll help you avoid pain and cost in the long run. And because you cannot compare these situations, you’ll never have any idea truly how much pain a good builder will save you by being able to identify issues before they become issues and solve problems before you even know you’ve got a problem. These are the guys that I see get passed over for the installer who’s going to put your cabinets in backwards (I literally have seen this).

DIY also costs more in the long run (most of the time)

You don’t know how much it pains me to admit this. I grew up around a family that was constantly remodeling and building. My grandfather was a builder and my father enjoyed carpentry in the evenings. My childhood home was constantly being improved; an addition on the front, a kitchen renovation, remodeling the attic, adding doghouse dormers, new windows, etc all through my childhood. So I love the DIY culture. I love what social media and Youtube have done for the DIY culture. BUT my professional experience paints a different picture of the DIY culture. It’s very common for me to get clients who walk into the showroom and insist they can install cabinets. They insist they can cut and install crown molding. They insist they can mount the decorative end panels. They insist they can field fabricate a toe kick platform (this is actually quite simple). They always insist they can do it while you’re both standing in the showroom. But for each of the examples above I’ve stood onsite with my DIY clients who’re scratching their heads when they realize how much harder it was to get an entire run of cabinets to be level than that Youtube carpenter made it look. It’s not a fun way to spend a day trying to clean a DIY’ers mess up.

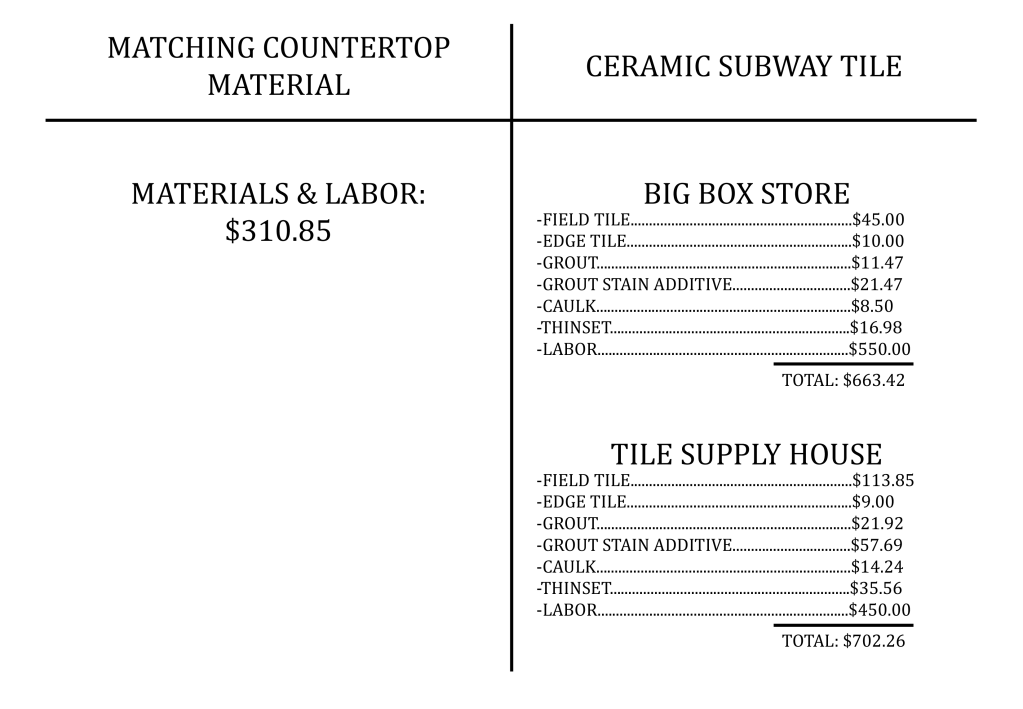

Prioritize costs over quality/ lopsided budgets

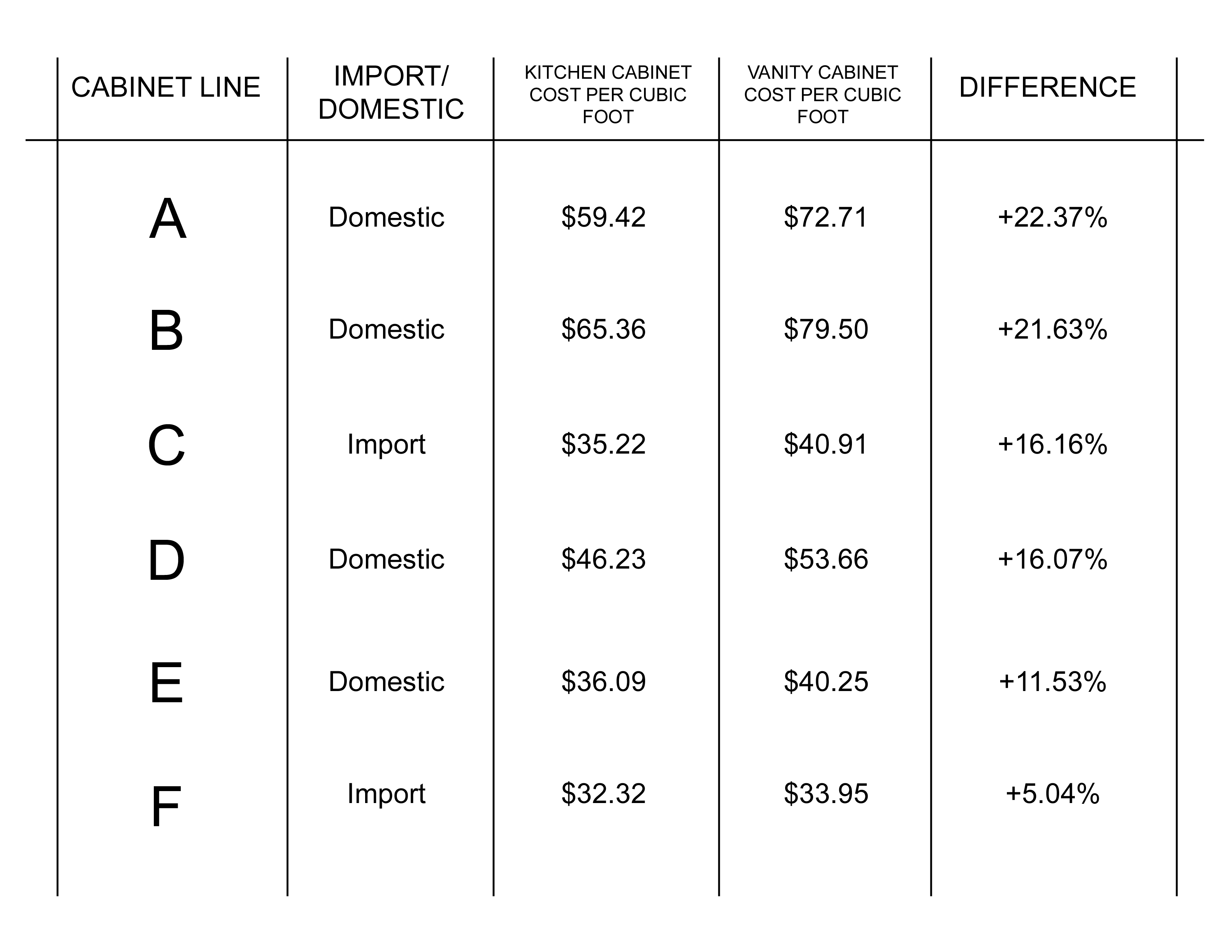

I’ve mentioned this above- clients choosing costs over quality. I guess there’s a reason we have certain terms, like pennywise and pound foolish- I guess these people have been around forever. I’ve seen people come to me with lopsided budgets. Budgets where they’ve got the appliance pricing triple that of the cabinet AND granite pricing. Think about that- they want to take high end designer appliances (which are really only good for 8-10 years) and surround them by junk cabinets and countertops because your budgets are so skewed. I’ve had people order kitchens where the entire cost is less than a single appliance in the space. Many times people have brought me kitchen designs that require custom door panels or custom sized cabinets, but the cabinet line they’ve chosen is so low, due to their budget, that we can’t accommodate the request because they simply don’t make the items. Don’t do this- don’t have lopsided budgets.

Major structural changes rarely pay off (monetarily)

I remember an early project in my career where I worked with a retired couple who just about rebuilt their entire first floor of their home which sprang from an addition of the rear. It didn’t start that way of course, it grew and grew and grew until the entire first floor was affected. It was a major project with so many learning experiences and I value the time so much. But looking back, and even during, we knew that these clients would never get their investment back in their home. Based on the neighborhood, the market at the time, and the total cost, I can’t see how they’ll ever get a return on the investment. Of course when I’m talking about return, I’m strictly speaking in terms of dollars. I am more than confident to say that the project returned for them as they knew this was a retirement home for them that they’d never leave. They weighed the options and determined that for them, the cost associated with living the way they wanted was well worth it.